How to Build the Vacvina Biogas Digestor

Contents

Introduction

Biogas obtained from the treatement of animal waste in order to produce energy can be very harmful for the environment if the exeeding biogas is released in in the atmosphere. In fact the GWP (Global Warming Potential - a measure of how much a given mass of greenhouse gas is estimated to contribute to global warming) of CH4 (Methane) is 21 times the one of CO2.

VACVINA biogas is a technology introduced in 1998 by The Center for Community Research and Development (CCRD) belonging to the Vietnam Gardening Association. VACVINA stands for VAC ("Vuon"-Garden, "Ao"-Pond, "Chuong"-Stable) of VietNam. The VACVINA biogas model is developed based on two existing technologies in Vietnam: (1) The fixed dome model came from China and India, and (2)The plastic digestion bag model was firstly introduced from Columbia to Vietnam in 1994 by doctor Reg Preston, Rector of the University of Tropical Agriculture. The VACVINA model is an innovative technology chosen by EASE Vietnam Programme[1] to promote in a commercialization approach from 2006.

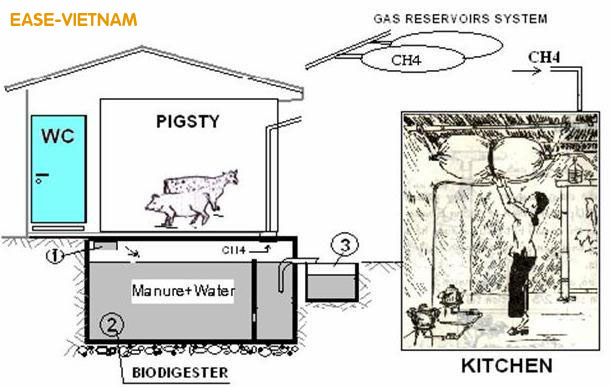

System

The system consists of a digestion tank (septic tank), nylon reservoir bag and inlet, outlet systems. The digestion tank is a flat-top rectangular underground digestion chamber. The external plastic gas reservoir is made of two to three layers of nylon bag. An ingenious system of inlet siphon allows the new material to be dropped into the surface of the fermenting liquid thus breaking any accumulated scum. The small outlet tank collect liquid waste from the digestion tank through a plastic tube.

The digestion tank:

The main digester is an underground rectangular tank made of bricks and mortar. However, the shape of the tank can be adjusted to the specific configuration and constraints of the family compound while retaining a sufficient volume. One of the great advantages of this model is that the concrete flat top of the digester can provide a clean and dry floor for the pigsty or stable. It also can be build as an integration of the toilet and the septic tank under the stable.

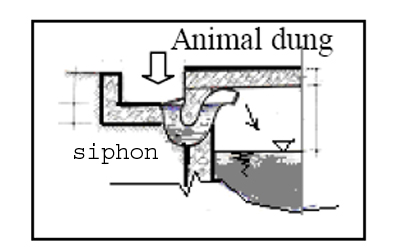

The inlet system:

The hole for the inlet pipe is 30cm diameter and starts from the top of the wall. It can be located on any wall of the digestion tank during the construction time. A siphon connect the mixing tank and the main digestion tank. The standard dimensions of the mixing tank are 0.2 m x 0.4 m with a depth of 0.3 m. This system prevents the formation of a scum layer by regularly wetting and mixing the surface with fresh input. (See picture 1)

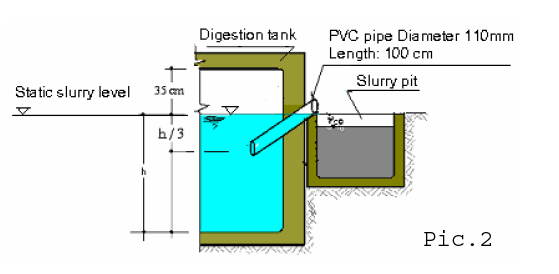

The outlet system:

The outlet pipe's length and position are important because they determine the level of slurry in the digester. The PVC pipe is 110 – 150 mm in diameter with a length equal to one third of the slurry height (80 – 100 cm). It must be positioned at a 45° angle, making sure it extends under the surface of the slurry the equivalent of one third of the height of the slurry. (See picture 2)

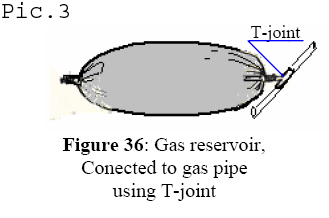

The reservoir bag:

The reservoir is made of two layers of 20-24μc polyethylene tubing, 100cm in diameter and 2.5 m in length capable of storing 1.8m3 of gas. One end of bag is tightly tied while the other is connected to the pipeline with φ21 plastic tubing.(See picture 3)

In order to ensure a rapid production of gas for cooking, it is advisable to prepare 700-800 kg of fresh dung (to be collected and stored in a 7-day period) as initial input. The ratio to mix dung and water is 1/5. After 5-10 days, gas will appear and inflate in the reservoir bag.

Video link

Video clip: http://www.youtube.com/watch?v=ne3RdAmPIbw

Contact

Research Center for Energy & Environment (RCEE)

Research Center for Energy & Environment (RCEE)

Address: No. 33, Trung Yen 9 Road, Yen Hoa ward, Cau Giay district, Hanoi, Vietnam

Tel: (+84-4) 6291 2407, Fax: (+84-04) 3786 8593, email: rcee.ease@gmail.com

Website : http://ease-vn.org.vn / http://rcee.org.vn

Related Articles

- Biomass (Technical Brief)

- Biomass and Liquid Biofuel (Technical Brief)

- How to Build the ARTI Compact Biogas Digestor

- How to Build the Vacvina Biogas Digestor

- How to Use Biogas

Categories

- Agriculture

- Biogas

- Community

- Ideas

- Small Business

- Difficult

- Global Technology

- Between 50 and 200 US$

- One Person and more

- Household

- Village

- Neighbourhood

- Application

- Principles

- Howtopedia requested drawings

- Howtopedia requested images

- Practical Action Spanish

- Requested translation to Spanish

- Requested translation to French